Figure 1. View of one of the two Vilafant footbridges. Photo: T. Michiels.

Location: Vilafant, Catalonia, Spain

Design engineer: Juan Sobrino, Pedelta

Owner: Administrador de Infraestructuras Ferroviarias (ADIF)

Contractor: Sacyr

Built: 2010 - 2011

Main span: 45 meters (148 feet)

Total length: 45 meters (148 feet)

Structural system: Vierendeel Truss

Figure 2. Transverse section showing the lightness and slenderness of the footbridge. Photo. T. Huynh.

Introduction

The Vilafant footbridges (see figures 1 and 2) over the high-speed railway from Barcelona to the French Border are a pair of identical 45.2 meters long bridges located in Vilafant, Catalonia. Vilafant is a small town of 5000 inhabitants located three kilometers southwest of Figueres and 150 kilometers north of Barcelona. Finished in 2011, the two bridges form an essential connection between the two sides of the town split by the high-speed line.

The two bridges were designed by the firm Pedelta and built under commission from Administrador de Infraestructuras Ferroviarias (ADIF), the Spanish railway infrastructure administrator. Pedelta is an international engineering design office founded in 1994 known for the use of advanced materials such as stainless steel and fiber reinforced plastics in structures. The Cala Galdana bridge [1] designed by Pedelta and finished in 2005 was the first duplex stainless steel road bridge in Europe and is an example of the innovative designs of the firm.

Pedelta is headed by Juan Sobrino (b. 1966, Figure 3), a Spanish bridge designer who received his civil engineering degree from the Technical University of Catalonia in 1990 and earned a PhD from the same university in 1994. In recognition of his work, Sobrino has received several awards over his carrier including the 2003 International Association for Bridge and Structural Engineering (IABSE) annual prize for members 40 years old or younger, for their “outstanding contribution to structural engineering” [2] and the 2012 Eugene C. Figg Jr Medal for Signature Bridges of the International Bridge Conference for the Triplets Bridges in Bolivia.

Figure 3. Juan Sobrino giving a lecture for the CEE 463 class at Princeton University, Fall 2014. Photo. T. Huynh.

Three main factors influence the creation of a bridge or civil engineering structure at Pedelta: the structure must meet high technical standards, be aesthetically pleasing and finally, exist in harmony with its surroundings [3]. Pedelta takes great care to include these aesthetical and contextual aspects in the design process. With each structure, the firm aims to reinforce the idea that civil engineers are more than just builders of bridges, roads, and other infrastructure. With astute attention to sustainability and the user experience, each design is an opportunity to establish the image of the civil engineer as a direct contributor to society. For Sobrino, keeping the work interesting means pushing the boundaries of what has been done, but always in the respect of the public and of ethical considerations.

“It is important (…) to balance technical and formal approaches without dogmatisms to create functional, aesthetically pleasant and contextualized bridges to serve public interest.”

Juan Sobrino [4]

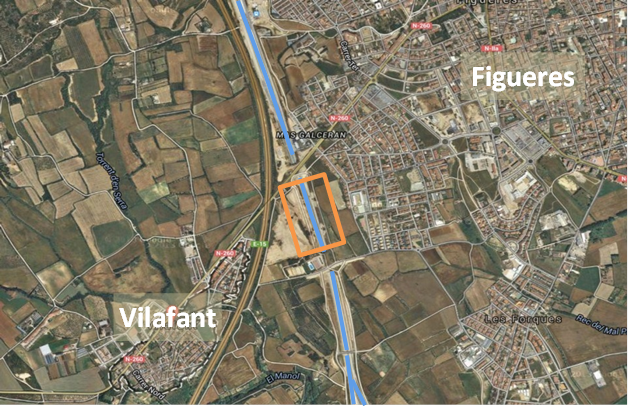

Origin of the footbridges

The need for the development of the two Vilafant footbridges arose from the construction of the high-speed railway line Barcelona – French Border. The railway was planned straight through the municipal land of Vilafant and would further divide the territory that was already split by the AP-7/E-15 highway. It would cut off the access to a school, limit the circulation towards some sport facilities, as well as significantly complicate the commute between Vilafant and Figueres for cyclists and pedestrians. Figure 4 shows the location of the project relative to the city of Vilafant at the bottom left, and the city of Figueres at the top right. Logically, this raised significant concern from Vilafant’s inhabitants, which was addressed by a promise of a full permeability and full integration of the new railway infrastructure. This permeability was achieved through the construction of the two Vilafant footbridges.

Figure 4. Location of the project site (orange box) on Vilafant municipal ground. The Barcelona-French border high-speed railway line is highlighted in blue. Source: Google Maps

Figure 5. View of the two footbridges and their surroundings. Photo. V. Charpentier.

While the current lack of development does not fully reveal the beauty and strong character of the footbridges, the original design showed a promising overall vision for the surroundings (Figure 5). The concepts of innovation and advancement manifest themselves in the bridges’ design, which can still be appreciated when crossing the bridge.

Description and structural behavior of the footbridges

The two footbridges are revolutionary because they employ materials that are not traditional in bridge design (see Figure 6): stainless steel and glass fiber reinforced plastic (GFRP). The resulting hybrid structure is both playful and elegant and provides an enjoyable visual experience. The strength of the steel paired with the lightness and transparency of GFRP creates a dynamic, elegant structure. With its translucency and organic green color, the GFRP panels evoke a sense of lightness, enhancing the normally mundane process of crossing a footbridge. Indeed, walking on the non-slip GFRP deck panels feels like walking on a much smaller, lighter structure.

Figure 6. Detail of the footbridge showing the use of stainless steel and glass fiber reinforced plastic (GFRP). Photo. T. Michiels.

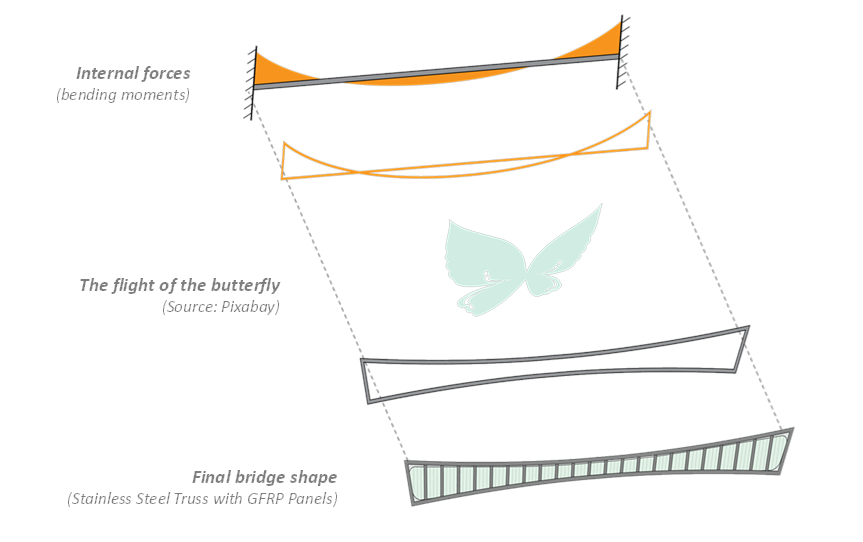

The footbridge deck consists of two Vierendeel trusses with double sheets of GFRP as structural webs, and a floor defined by GFRP panels supported on stainless steel girders perpendicular to the footbridge axis [3, 5]. The Vierendeel trusses are elastically fixed to the abutments. As a result, bending moments are maximum (in absolute value) at the abutments and the Vierendeel trusses have greater depth at the supports (3.4 m) than at mid-span (1.2 m). The shape is reminiscent of a butterfly spreading its wings, further articulating the theme of flight and lightness. Figure 7 illustrates these ideas. The result is both elegant and efficient as it provides greater depth where bending moments are higher.

Figure 7. Generation of form of the Vilafant footbridges. Image. T. Huynh.

Additionally, the use of GFRP panels has several advantages. Its most significant contribution is the improvement of the dynamic behavior of the bridge. The combination of GFRP with stainless steel produces a hybrid structural system with good damping qualities. Damping describes how quickly the bridge returns to equilibrium after the application of a dynamic load, such as pedestrians crossing or jumping. By reducing the spacing between the bolts connecting the GFRP to the steel, the structural damping is further improved. It was also found that the introduction of the GFRP panels slightly reduces the potential for members to fail under buckling loads because the panels somewhat lessen the internal forces experienced in the members of the truss and stiffen the compressed members.

Other benefits of GFRP include its ease of construction, aesthetic properties, and sustainability aspects which may serve as a basis for utilizing GFRP. Furthermore GFRP was a good solution for pedestrian protection. As the footbridge is situated over a high speed rail, pedestrians must be protected accordingly and protective barriers are required. The GFRP panels fulfill the same role as a less appealing chain fence. It is also a refreshing alternative to the more conventional bracing method of diagonal members.

Conclusions

The cost of the overall project was US$ 5 million [3]. This cost is higher than the cost of a standard solution for a footbridge, but it is justified given the innovative techniques and materials used. Investing in the use of innovative, environmentally friendly and low maintenance materials is essential to advance the art of bridge design. Therefore these structures should be seen as prototypes which will always be inherently more expensive. We should try to learn from them how we can efficiently use GFRP and hope that one day the surrounding green area is improved so the bridges can be fully appreciated.

References

[1] J.A. Sobrino. “Stainless Steel Road Bridge in Menorca, Spain." Structural Engineering International 16(2):96–100, 2006.

[2] IABSE Prize list of awardees. www.iabse.org. Retrieved on April 27th, 2015.

[3] www.pedelta.es

[4] J. Sobrino. "A Bridge is More Than a Bridge: Aesthetics, Cost and Ethics in Bridge Design." Structural Engineering International 23(3): 340-345, 2013.

[5] J. Sobrino. “Light and durable Steel-GFRP Pedestrian Bridges." Proceedings of the 35th Annual Symposium of IABSE / 52nd Annual Symposium of IASS / 6th International Conference on Space Structures, London, United Kingdom, 2011.